Innovating the factory with data for more sophisticated manufacturing

What we do

SATO enables digital transformation (DX) via data capture and digitization of all aspects of factory activities. We help factories flexibly identify and locate assembly parts, tools and palettes so robots and machines can interact with them and further automate operations.

Factory operators need to see inventory status and visualize their operational efficiency in real time. We help manufacturers collect data significant to factory operations, visualize it, and link it to their WMS or MES systems for big data insights. By connecting manufacturers to their on-site small data, Our solutions nimbly innovate their factory processes for benefits in the supply chain downstream.

Solutions

- Microlabels for forward & backward traceability

- Location tracking to streamline incoming and outgoing shipments

- RFID tracking solutions to capture data automatically in real time

Testimonials

- Drastic productivity gains for food manufacturer through labeling automation (Otafuku Sauce Co., Ltd.)

- Automotive maker automates label printing, raising productivity by 18% (Toyota Motor East Japan)

Announcements

-

Implement contactless temperature check-ins with secure record-keeping.

Temperature check (for workplaces)

Challenges

- Thorough safety measures needed, starting from point of entry

- Temperature screening and data collection managed manually

- No real-time reporting of individuals with at-risk temperatures

-

Solution

Take and automatically store temperature readings for staff and visitors as they enter, issuing them with label-based entry passes if necessary.

- Detect symptoms to help reduce virus transmission

- Provide assurance with labels that can serve as proof of normal temperature

- *Not available in South America.

- *For other countries/regions, please contact your nearest SATO office to find out more.

-

Use stickers to help customers practice safe distancing.

Floor marking

Challenges

- Inadequate safety precautions in stores

- Close proximity between customers, especially at checkouts

-

Solution

Clearly mark out distance required for social distancing to get customers in line without standing too close to one another.

- Floor stickers that can be rolled out quickly and easily

- Durable for use in high footfall areas

- Provide visual cues on where to queue for safe customer spacing

- *Availability varies by country/region. Please contact your nearest SATO office for more information.

-

Use stickers to promote practices that prevent infection.

Awareness-raising stickers

Challenges

- Inadequate safety precautions at workplaces

- Handwashing and other instructions not easy-to-understand for everyone

-

Solution

Put up stickers about infection prevention at highly visible areas such as entrances and restrooms to raise hygiene awareness in employees.

- Stickers to reinforce hygiene routines for a safe working environment

- Can be printed in standard layouts or designs original to customers

- Can also support images or texts in different languages to suit foreign workers

- *Availability varies by country/region. Please contact your nearest SATO office for more information.

-

Keep workers safely distanced and printer operations running stably.

Cloud-based support services

Challenges

- Cautious about admitting external technicians to sites due to virus fears

- Workers touch printers too often for configuration or troubleshooting errors

- No business continuity plan to sustain printer operations during emergencies

-

Solution

Oversee printer operations 24-7 via a cloud network to minimize errors/downtime and speed up recovery through preventative maintenance and remote support, reducing reliance on on-site servicing by outside engineers.

- Use an online maintenance service to monitor printers remotely and replace printer parts before they wear down to ensure worker safety and operational stability

- Also use a cloud-based data management service to always provide printers with the latest labeling data

- *Availability varies by country/region. Please contact your nearest SATO office for more information.

-

Introduce automation to reduce close physical contact between workers.

Auto-labeling & packing

Challenges

- Workers at risk when performing labeling or packing in close proximity

- Possible production disruptions when workers are affected by the virus outbreak

- Lower productivity as factories seek to operate safely with less manpower

-

Solution

Automate label printing/applying and carton forming/sealing operations to keep fewer workers on site and distance them more effectively.

- Use automation to help protect labor force

- Ensure stable production even with manpower limitations

- *Availability varies by country/region. Please contact your nearest SATO office for more information.

-

Track assets efficiently using contactless RFID tags.

Asset management

Challenges

- Workers subject to crowded/close-contact settings during stocktaking

- Handwritten logs not accurate or complete

- Real-time tracking of asset movements not possible

-

Solution

Manage assets with contactless RFID, which allows for quicker and more frequent stocktaking to improve inventory accuracy.

- Read multiple RFID-tagged assets at once, saving labor and up to 95% of stocktaking time

- Automate and track loan-outs/returns with searchable database

- Offered as a ready-to-use solution for quick and easy deployment

- *Availability varies by country/region. Please contact your nearest SATO office for more information.

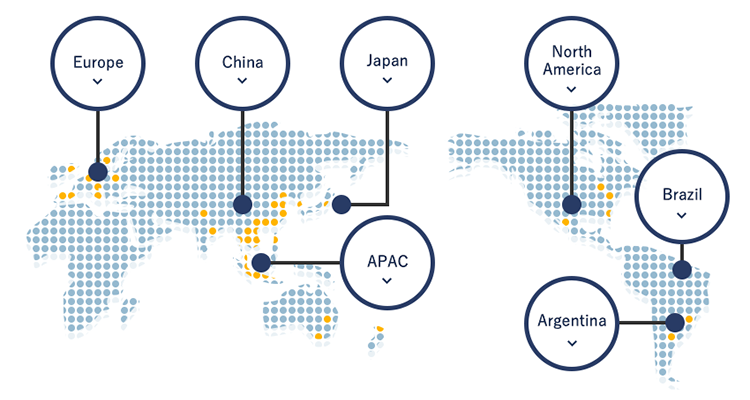

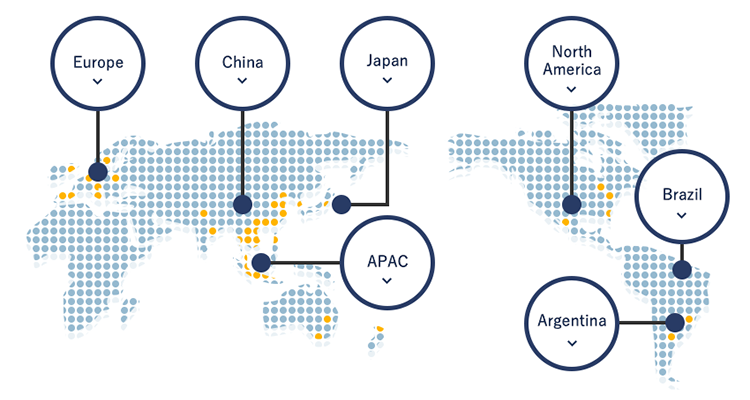

Find SATO where you are