- From left: Koichi Hashimoto (Sales, SATO Healthcare), Kazuyuki Kobayashi (formerly in R&D, SATO Corporation), Hiroshi Tomozawa (Business Planning/Development & Sales, SATO Healthcare), Satoru Honda (R&D, SATO Corporation)

- *All details as of time of interview (January 2023)

In hospitals, wristbands are commonly used to identify patients by name, date of birth and other personal information. SATO boasts the top market share for patient ID wristbands in Japan, but how did it all start? How did its wristband lineup come to be and where is it headed? Let’s hear from salespeople (names indicated in red) and R&D members (names in blue) involved with the SATO wristband from its inception.

Won’t patients feel like prisoners?

Hashimoto To understand SATO’s patient ID wristband, let’s start with its history. Back in the late 1990s, some hospitals in Japan were using handwritten wristbands, but the practice at the time to identify patients was simply to call them out by name. This left room for human error, which could result in clinical incidents and near miss incidents. Some patients, due to their medical conditions, would acknowledge names incorrectly called upon or have difficulty answering. We thought the situation called for a barcode-based patient identification system so we started development on printable wristbands using our recently launched desktop label printer.

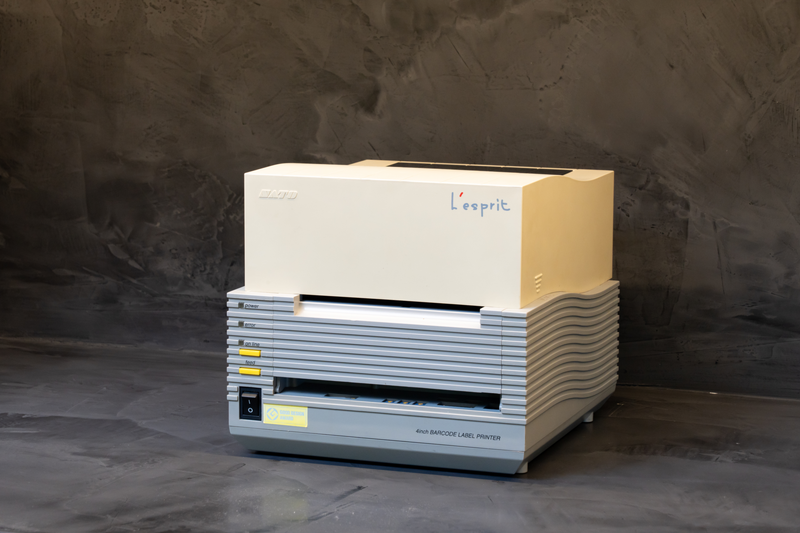

Our first wristband printer model

Our first wristband printer model

Kobayashi Taking on a totally new field was exciting for the R&D team, but we were often unsure how to best move forward. We knew how to develop barcode labels for retail goods, but the wristband was very different. People had to wear it for long periods of time, meaning it must be strong yet comfortable and hygienic. There were also technical difficulties we needed to overcome to enable smooth printing on the thick wristband material while ensuring print durability. I recall partnering with a company that specialized in medical supplies like bandages. They helped us pick the material most compatible with our printer and work out other specifications one by one.

Honda To improve comfort, for example, we added embossing to the reverse side of the wristband so that it would make fewer points of contact with the skin. But that made the wristband thicker and its surface uneven with tiny bumps and recesses, so we had to go back again to change our material, ink and printing process accordingly.

Hashimoto With R&D underway, the sales team visited different hospitals to introduce our new wristband but we were met with criticism. “Are you telling us to number our patients?” “Won’t patients feel like prisoners?” Most hospitals did not buy into our proposal in the beginning.

Honda But things changed in 1999 when news of a hospital that performed surgery on the wrong patient grabbed headlines, prompting hospitals nationwide to reevaluate their risk management policies to prevent errors.

Trying our own inventions as a team

Tomozawa Many hospitals started contacting us and we had to speed up development. 1999 was the year we entered the health care business.

Hashimoto As a common practice back then — and even today — all team members in R&D and sales handling new products would test them themselves. I vividly remember my days of wearing our first wristband prototype everywhere to check for potential issues. I bathed, got changed, and even slept in it!

Keeping our hands-on spirit alive: Tomozawa, posing with a new SATO wristband he currently wears for testing

Keeping our hands-on spirit alive: Tomozawa, posing with a new SATO wristband he currently wears for testing

Kobayashi I had my family wear them (laughs). And of course, we got the prototype tested externally by professional institutions for all metrics we could think of and kept improving its performance. We finally succeeded in releasing our first-generation, printable patient wristband in 1999.

Honda That first year was merely the starting point. As hospitals began using our wristband, new needs surfaced, which we set off to address by developing a string of new wristband products.

Tomozawa Our R&D team first looked for softer materials to improve wearability, as requested by many hospitals. The change in material, however, led to print wear and contorting issues, which the team had to work on relentlessly before launching an improved version in 2005.

Hashimoto With that new version, we expanded our product lineup beyond inpatient wristbands to include simplified outpatient wristbands1 (for medical checkup purposes) and maternity wristbands1.

SATO’s maternity wristband separates into two right at delivery to be worn by baby and mother to prevent mix-ups

SATO’s maternity wristband separates into two right at delivery to be worn by baby and mother to prevent mix-ups

The importance of going on site

Hashimoto I’m sure we gave the R&D team a tough time, as they had to develop different wristband specifications to match all the new requests we kept receiving from new users and applications.

Honda You sure did (laughs). But not meeting those needs wasn’t an option, as lives were at stake with our products. As we worked to improve the product, we got many ideas from visiting hospitals and seeing how our printers and wristbands were used on the front lines.

Kobayashi Thanks to our salespeople who made sure to take us along on customer visits, we were able to meet medical staff and hear their feedback directly. We learned many things we wouldn’t have realized sitting in the office, and that helped our R&D work greatly.

Tomozawa We later released a much softer wristband in 2012 and an enhanced version1 a year later based on user input. And as used ink ribbons could potentially divulge personal information, we also developed and started selling security ribbons1 to give hospitals greater peace of mind.

Hashimoto It was also around that time when we spun off our health care business into a new company called SATO Healthcare. For me and my colleagues who started it all from scratch, it was beyond gratifying to see our operations grow into a business pillar for the SATO Group.

From ‘nice-to-have’ to ‘must-have’

Honda The R&D team kept itself busy with wristband development even after the establishment of SATO Healthcare. There are many stories I could share, but they all involve one thing in common: close teamwork between sales and R&D members to understand hospital operations and needs. Every time we make progress in R&D to address one customer pain point, another pain point comes along. The cycle just keeps repeating itself, and that’s how we were able to expand our wristband offerings into the diverse lineup it is today.

Tomozawa We’re supporting people who save lives, so it’s only right that we work with the same dedication, seeing to each request and thinking of everything possible to present solutions that fulfill their need. And when they thank us for an idea that exceeded their expectations, the sense of achievement we get is unbeatable.

Hashimoto Receiving words of appreciation definitely makes us happy, but what makes us even happier is the fact that wristbands have now become commonplace in hospitals everywhere and that a huge majority of those wristbands in Japan are SATO’s.

Kobayashi For the younger generation of nurses, wristbands are part of their work from day one. It’s no longer a nice-to-have but a must-have item for every hospital. Seeing how the product now functions as the norm for patient safety, I’m truly honored as an R&D person to have played a part in developing SATO’s first wristbands.

Taking our wristbands to the next level in a post-pandemic world

Hashimoto Patient wristbands are ever-evolving. At SATO, we continue to seek greater comfort in our wristbands with softer material. We also work to meet newer needs for technologies such as RFID, which allows contactless reading of data that became a necessity in hospitals during the pandemic.

Honda We were already developing and selling RFID-embedded wristbands before the pandemic brought about a sudden boom in inquiries for the technology. Unlike barcode wristbands that need to be held right up against a reader device, RFID wristbands can be read from a distance without making contact.

Tomozawa They can be read from over a blanket, without waking the patient up. Nurses can even perform three-point verification2 smoothly when administering medication. While we didn’t expect the pandemic-induced spike in demand, we know how RFID can help ease mental and physical strains experienced by medical staff, so we love seeing it used more. We hope to reach more hospitals by adding to and diversifying our wristband lineup for a variety of applications.

A SATO RFID wristband in Japan (design varies by country/region)

A SATO RFID wristband in Japan (design varies by country/region)

Hashimoto In 2022, we shifted our business concept from Patient Safety to Patient Happiness. It expresses our commitment to offer health care solutions that seek the happiness beyond safety, for which the key is to help hospital staff work more efficiently so as to improve the quality of care for their patients. RFID wristbands are a part of such solutions we will be creating, as we keep with our founder’s spirit of Ceaseless Creativity to continue challenging ourselves to innovate health care for a better future.

- 1.Product availability varies by country/region. Please contact your nearest SATO office for more information.

- 2.Scanning of patient ID, nurse ID and medication label to ensure that the right medication is given to the right patient while recording who administered it.

SATO’s health care solutions

Our “Patient Happiness” concept is our commitment to delivering health care solutions that improve hospital workstyles and the quality of life of medical practitioners to seek the happiness beyond a patient’s safety.

Profile

- SATO Healthcare Co., Ltd.

- Based in Tokyo, SATO Healthcare was established in 2014 and provides comprehensive auto-ID solution planning and implementation for the health care industry, utilizing barcodes, RFID, printers, wristbands, and other hardware and medical label supplies.