Dec 09, 2024

SATO Holdings Corporation and Nakadai Holdings have been collaborating since 2023 to develop a comprehensive traceability system that aims to contribute to the circular economy by providing end-to-end visibility of waste collection, processing and recycled material production.

The companies have successfully developed a digital system that tracks and stores data throughout the entire process, including manual disassembly, sorting and waste processing. In August 2024, SATO conducted a new proof of concept (PoC) at Nakadai's recycling facility. We are pleased to announce that this trial demonstrated both the system's effectiveness and its ability to capture crucial data required for resource circulation.

Moving forward, the waste traceability system will be implemented in daily operations at Nakadai's facility. The companies plan to conduct additional trials with the goal of commercializing the system for other recyclers and manufacturers' recycling facilities.

Data collection processes

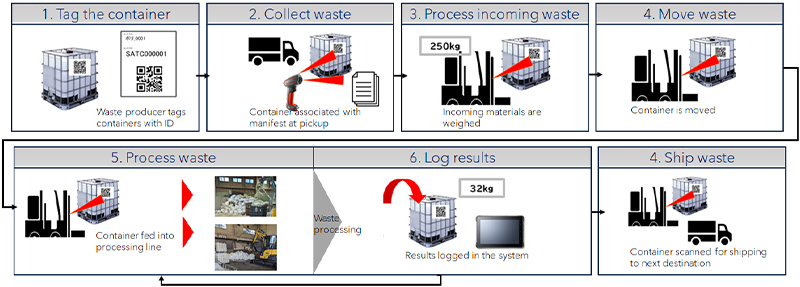

In 2023, SATO and Nakadai completed an initial trial focused on streamlining waste collection with the use of AI. This involved installing cameras at waste storage areas of Nakadai's corporate clients to monitor waste accumulation through AI-powered image analysis. The latest PoC builds upon this success, focusing on digitizing the entire process from when containers are tagged to shipment to their final destination.

The system captures data at each key stage of recycling: tagging, collection, receipt, transfer, recycling, logging and shipping. Each waste storage container is assigned a unique ID label, enabling digital tracking and recording throughout all processes at Nakadai's facility from receipt to final shipment, and real-time monitoring of recycled material production. It gives the recycler the potential to streamline each procedure and traceability over their entire process.

Key innovations

SATO's system successfully implemented several breakthrough capabilities

- Container-level ID management linked to manifests and content

- Detailed tracking of content, storage location, weight and process checkpoints by container

- Comprehensive documentation to link incoming pre-processed containers and outgoing post-processing containers (containing both waste and material of value)

- Data logging when multiple containers are combined in a single process

- Enhanced manifest deadline management through multiple manifest linkages to container IDs

- Detailed operational visibility of who performed what process, when and where, using operational data rather than estimates

- Weight-based management from receipt through processing to shipping

- Real-time inventory visualization by facility area and receipt date

Vision for the future

The digitization of recycling processes enables precise quality grade management and information tracking of recycled resources. Despite the inherently variable nature of waste collection, comprehensive digital tracking post-collection ensures consistent shipment quality and reliable quality assurance. Digitization also enables the sale of verifiable and trustworthy recycled materials.

This system also helps standardize recycler operations and identify process challenges, serving as a valuable tool to support waste management companies in their transition to becoming reliable recycled resource suppliers.

SATO HQ showroom

A booth on circular economy solutions has been set up at the SATO Tokyo showroom in October 2024, offering details on the system implemented in Nakadai's recycling facility and an overview on how SATO recycles its label printers. Visitors can experience firsthand how giving every 'thing' an ID connects it to the world to enable digital product passports (DPP) and other future sustainable resource management methods.