PT. Sigma Cipta Utama (SCU), a subsidiary of PT. Elnusa Tbk (subsidiary of Pertamina) was established in 1980.

They specialised in a wide range of data management services, and safekeeping of their customer's assets which includes hard copy documents, magnetic tapes and cartridges.

Customer challenges

Limitations of Existing Barcode System

Barcode scanning required line of sight which made it harder for SCU to handle increasing volume of assets items efficiently. In addition, due to barcode readability problems, it was challenging for SCU to achieve asset control accuracy.

Provide Added Customer Assurance and Peace of Mind

SCU wanted to achieve real-time end-to-end visibility of clients' assets so as to provide full assurance and peace of mind to customers.

Tedious and Time-Consuming to Locate Assets

In a warehouse setting where assets may be stored in high and hard-to-reach locations, it was hard for workers to locate and pick the correct items on demand each time.

SATO RFID Asset Management Solution Drives Real-Time Asset Traceability, Enhances Efficiency and Productivity

Given the limitations of barcode system and the increasing volume of assets, SCU turned to SATO RFID solution to help them manage and control all of their clients' valuable assets which were kept under their care.

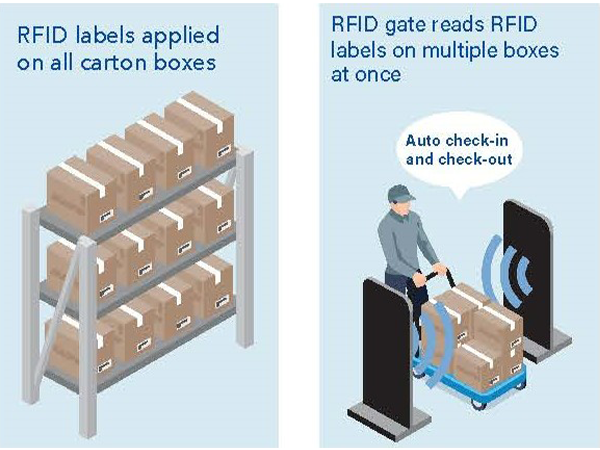

To achieve asset traceability, SCU printed and encoded RFID labels using CL4NX printer and applied them on each asset item when received. Asset movements were tracked and recorded when scanned by RFID gates installed in the warehouse and staff were able to utilize RFID handheld readers to speedily locate and scan items for pick-up.

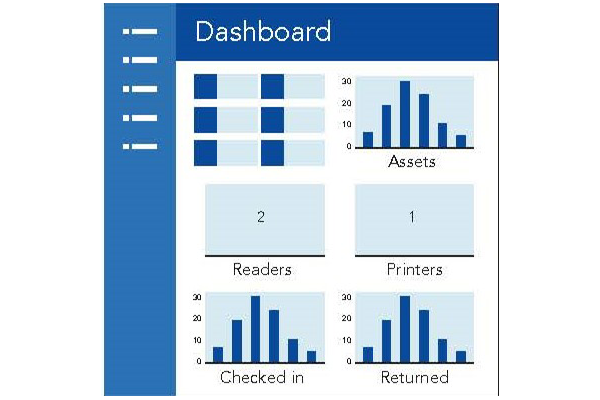

SATO software dashboard enabled the tracking of all incoming and outgoing assets in real-time. This enabled SCU to provide added assurance and peace of mind to their clients that their assets are safe and well-accounted for.

CL4NX Plus industrial printer

CL4NX Plus industrial printer

Customer value

Asset traceability and accuracy

Desired assets can now be located and picked up more speedily with ease and hassle-free manner.

Speedy and hassle-free process

SCU wanted to achieve real-time end-to-end visibility of clients' assets so as to provide full assurance and peace of mind to customers.

Operational efficiency and productivity

Replacing barcode with SATO RFID solution has streamlined the customer's operations. Less manpower is required with time savings up to 50% achieved for each stock-take.

RFID software dashboard

RFID software dashboard

Barcode system requires scanning of each box one at a time

Barcode system requires scanning of each box one at a time

RFID allows for automatic check-in and check-out which saves time and efforts

RFID allows for automatic check-in and check-out which saves time and efforts

Locating a specific asset is fast, easy and hassle-free

Locating a specific asset is fast, easy and hassle-free

After implementing SATO RFID Asset Management Solution for the past six months, we are certainly reaping the benefits it has brought us.

Our overall business operations are now more productive, with up to 50% time savings achieved for each stock-take.

More importantly, we are well-positioned to fulfill our continued committment to our clients, to be their trusted choice for all their data management and storage requirements.

Mr.Lalang Sugiri

Warehouse Manager

PT. Sigma Cipta Utama