Jan 10, 2024

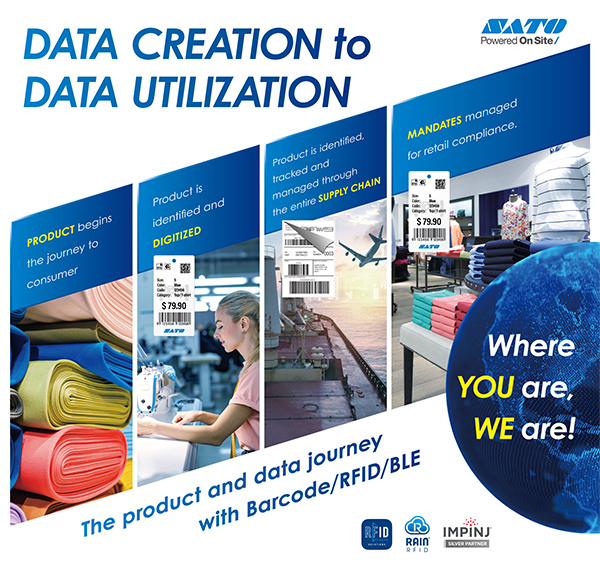

SATO America, LLC, a leader in modern identification and labeling solutions, will demonstrate its latest suite of digital transformation solutions at NRF Big Show in New York City from January 14–16 on the theme of “Data Creation to Data Utilization.”

Without reliable big data, retailers cannot truly transform their operations. To forecast more accurately, retailers need real-time data on inventory levels, locations and movements of products at various stages of the supply chain. SATO is showing its latest solutions that digitize critical bottlenecks across the chain.

RFID source tagging in the factory

A cloud-based encoding and logging solution developed in collaboration with Loftware digitizes retail tagging activities, keeping a detailed record as to who printed the label, when and what data was printed from the printer. Keeping these logs will enhance total operations for retailers by providing a secure, unique record of every encoded tag for total traceability.

Automated labeling in the DC

SATO America will demo its Automated Robot Labeling System which can be taught how to dynamically label items of varying form factors, sizes and position on the product to move products through the distribution center (DC) faster than ever.

Mobile labeling in the DC

SATO’s mobile 4-inch PW4NX, which can be mounted on forklifts for mobile printing in the DC, provides the fastest, highest quality mobile printing in class, even on low battery. This reduces read errors to streamline DC operations while lowering total cost of ownership1.

Streamlining incoming and outgoing shipments

With UHF tunnel readers and a central data management dashboard, retailers can greatly streamline their inventory control operations as well as packing and shipping. The UHF platform as a service (PaaS) dashboard from Chainlane provides centralized visibility across the chain to understand and improve operations.

Tracking temperature on the move

Wiliot’s BLE tags, SATO’s CL4NX Plus and Energous’ powerbridge provide a powerful solution for food safety and traceability and even waste management.

Ingredient labeling and markdown automation

Finally, allergen labeling in compliance with the FDA Food Safety Modernization Act (FSMA) and AI markdown automation can improve food-loss management and optimize in-store operations. The SATO solution allows retailers to print nutrition labels, directly supplying the printed data, printed time, expiry date and quantity back to their systems. These data can be combined with POS data to enhance store operations.

For more details, please visit the SATO booth #4456.

1.A metric that measures the amount spent over the lifetime of an asset

*All company names and product names included above are properties and trademarks or registered trademarks of their respective companies.