SATO, a global pioneer in the development of auto-ID and labeling solutions and ZMP Co., Ltd. (hereinafter ZMP) announced Visual Warehouse® for CarriRo®, an integration of the CarriRo® AD autonomous delivery robot from ZMP and SATO’s route navigation solution Visual Warehouse® to minimize the walking distance of pickers in the warehouse and distribution center.

Picking generally accounts for 60 percent of all warehouse operations, which mostly involves walking. Reducing the walking distance of picking workers is one of the most effective ways to increase productivity, even when the flow of goods increases.

Visual Warehouse is a navigation system that uses a unique algorithm to calculate the shortest path for pickers. It provides the shortest route to the goal determined and indicated on the virtual map based on the coordinates of inventory and the current location in the warehouse which is declared by the workers via handy terminals.

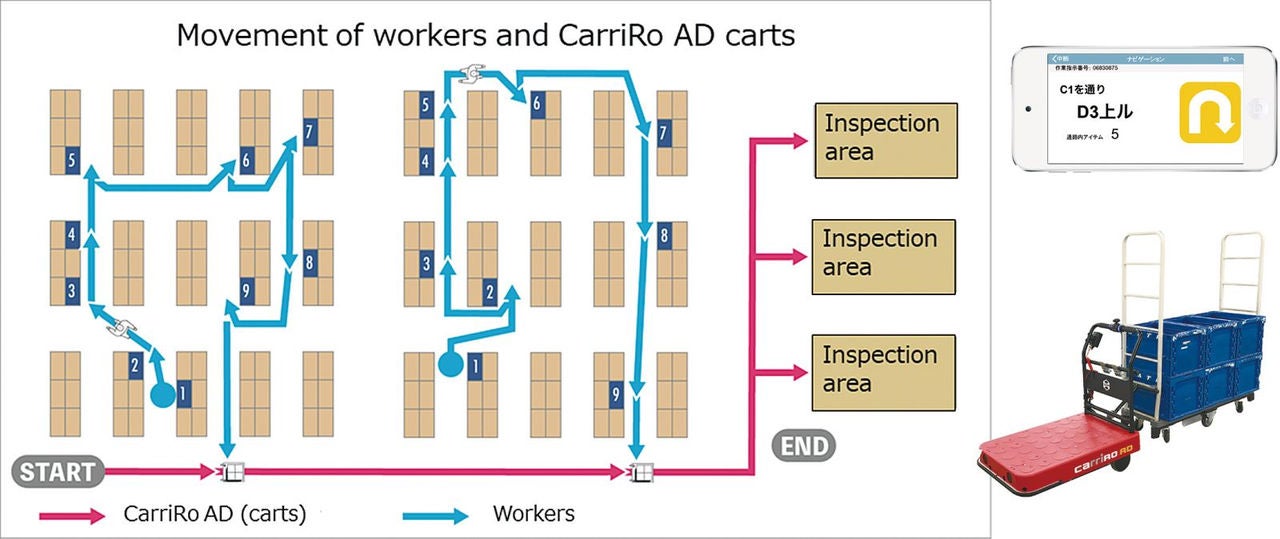

Visual Warehouse for CarriRo adds the shortest route for the worker and optimal junctions to meet the CarriRo AD robot to the route map as markers while the robots move around the facility autonomously and wait at the optimum meeting points.